Shobai Automation is a EOAT Robot Tooling Component Manufacturers in Brazil, Suppliers, Exporters in Brazil and many other countries.

We provide the below-mentioned detailed information about our products to assist you in finding the ideal fit for your business requirements at a very reasonable cost.

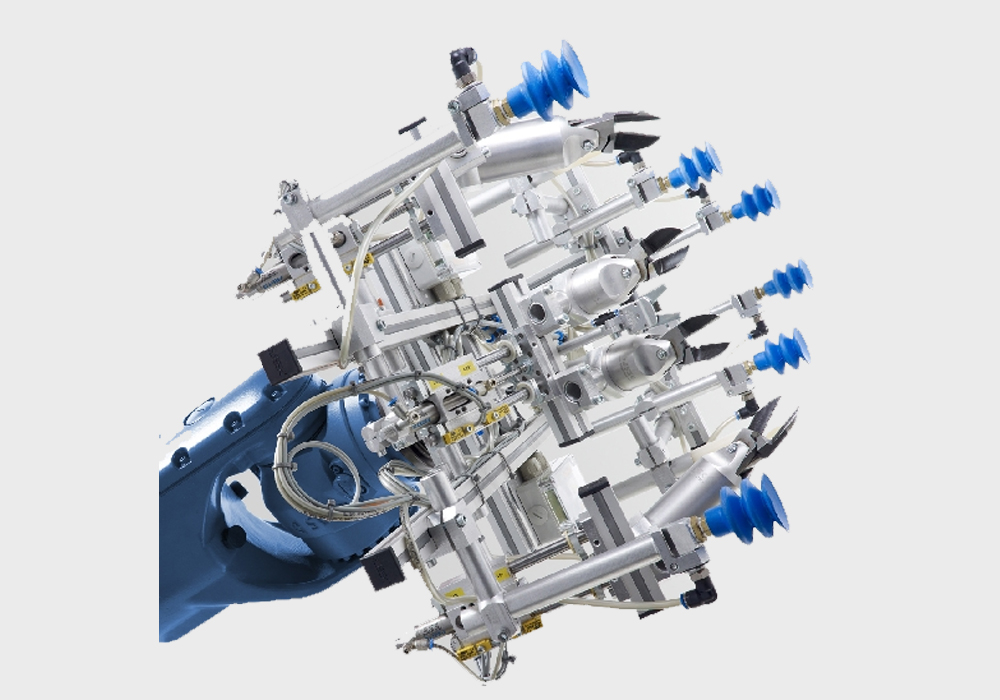

EOAT Robot tooling Component means the specialised equipment attached to the end of the robotic arm. It functions as the hands of the robot, helping it to interact with the objects and perform various tasks.

It is mainly used to grip, hold, and manipulate objects from one place to another during automated processes. It is used in many industries like welding industries, assembly industries, packaging industries, Pharmaceutical and medical industries.

1. Enhanced Flexibility and Versatility

2. Increased Productivity

3. Improved Precision and Accuracy

4. Enhanced Safety

5. Cost Savings

End of Arm Tooling (EOAT) Solutions helps in automation which reduces the need for manual labour and leads to significant cost savings in labour expenses.

Our End-of-Arm Tooling (EOAT) and 3D printing systems have high precision and accuracy which reduce material waste, leading to cost savings in raw materials and higher production efficiency.